Challenge

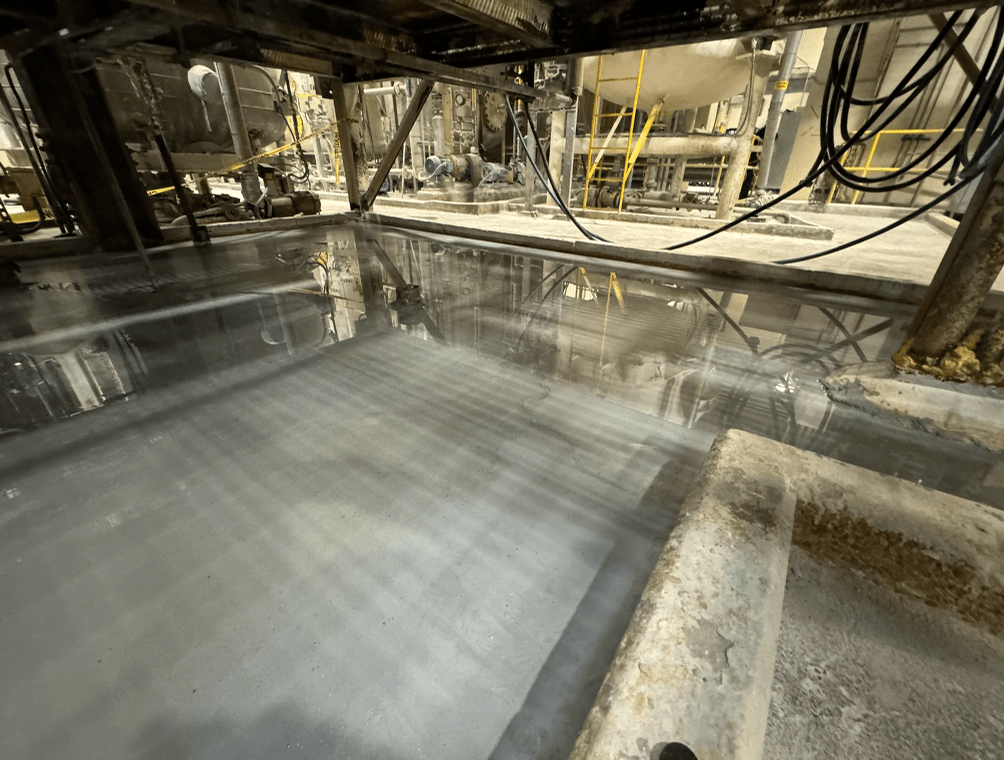

A major chemical plant faced recurring issues with a deteriorating concrete floor located beneath a belt extractor. Years of chemical exposure and constant vibration from heavy equipment had significantly weakened the area. Prior repair attempts using standard concrete and cement grout had repeatedly failed—crumbling under stress and ultimately causing leaks onto lower levels.

With only a narrow two-day window available, the floor had to be repaired in parallel with scheduled belt extractor maintenance. The customer required an industrial-grade solution that could be installed quickly and would withstand the plant’s harsh operating conditions—reducing the need for repeated shutdowns and repairs.

Solution

The maintenance team selected Devcon® Floor Patch™ Resurfacer, a self-leveling, epoxy-based compound specifically engineered for industrial flooring repair. Unlike traditional concrete or grout, this high-performance resurfacer is designed to withstand heavy mechanical stress and vibration, making it ideal for use in facilities with dynamic equipment.

Key reasons for choosing Devcon Floor Patch Resurfacer included:

- Industrial Strength & Durability: Resilient against vibration and chemical exposure, ensuring long-lasting repairs.

- Rapid Installation: Significantly reduced installation and curing time compared to conventional materials.

- Minimized Downtime: Allowed the plant to complete flooring and belt repairs in a single shutdown, reducing operational impact.

Implementation Highlights

- Fast Installation: After removing the damaged flooring, 636 ft² (59 m²) of Devcon Floor Patch Resurfacer was applied and leveled within just two hours.

- Quick Cure Time: The product cures at room temperature and typically reaches full strength within 24 hours, allowing rapid return to service.

Results

-

High-Speed Repair with Long-Term Value:

The Devcon epoxy system delivered a fast and reliable repair within the customer’s tight timeline—eliminating the failures caused by previous patching attempts. The plant avoided extended downtime and costly future repairs, staying both on schedule and on budget. -

Customer Satisfaction & Future Projects:

Impressed by the performance and efficiency of the solution, the facility has since extended the use of Devcon products across other areas of the plant.

Leave a comment

All comments are moderated before being published.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.